mailFactory® PerformanceAnalyzer evaluates and visualizes important key performance indicators (KPIs) and helps to optimize your document output management.

PerformanceAnalyzer is provided as a service within the mailFactory® Manager Sphera architecture. The service actively supports the reaching of operational excellence in your document output management environment.

To fulfill this goal it is essential to supervise, analyze and improve the production and its processes.

mailFactory® PerformanceAnalyzer easily uncovers hidden losses and evaluates the overall equipment efficiency (OEE) and plant utilization.

PerformanceAnalyzer provides all the relevant key data to implement quality concepts in the production, like Six Sigma, Total Productive Management (TPM), Lean Manufacturing etc.

Offered as a cloud-based service it relieves you from supplying the required IT infrastructure and simplifies the integration.

Main features

Key Performance Indicators

- Plant utilization and productivity → Total Effective Equipment Productivity –TEEP

- Plant efficacy → Overall Equipment Effectiveness –OEE

- Shift and daily production (target/actual/trend)

- Mean Time to Recover, –MTTR, or Mean Time between Failure, –MTBF

- The different KPIs are graphically visualized as individual widgets on the dashboard and give a fast overview of the whole production site. The layout of the information is user specific and can be positioned individually.

Drilldowns let you analyze profoundly the main reasons for losses. Pareto diagrams guide you easily to the events with the most negative impact in the production cycle.

Factsheet PerformanceAnalyzer

563 kB

Are you aware of your hidden production capacity?

Machines and systems tend to be some of the largest investments that a company makes. It is therefore essential to utilise them optimally, so that they ultimately achieve a high return on assets (ROA).

System utilisation, availability and performance are often sub-optimal!

A fact?

An inserting system often holds much more potential than is actually utilised: without analysis, checks and monitoring, overall equipment effectiveness (OEE) tends to lie around the 40% mark.

Uncover your hidden production capacity!

To raise the effectiveness and efficiency of your processes and systems, you need a precise grip on your production performance data. With the mailFactory® PerformanceAnalyzer you can go on to achieve considerable cost savings while making your equipment more effective.

Imagine you could unlock the hidden capacity of your existing machines with mailFactory® PerformanceAnaylzer and reach an OEE of 85% to match other industries. You make best use of existing resources and by doing so revitalise production capacity that was hidden in the background.

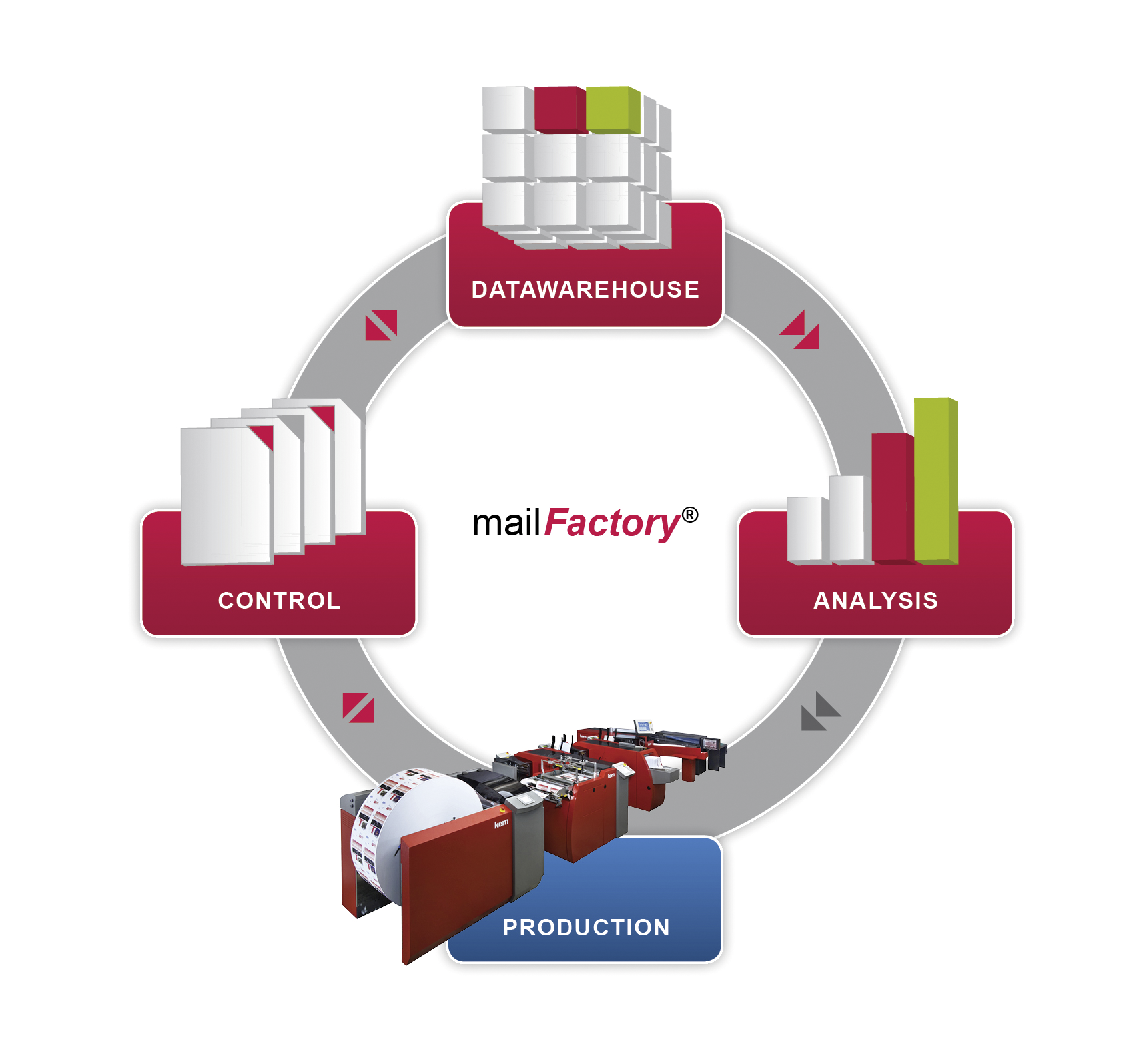

Data Flow Description

The incoming production data is collected locally at the production environment. The mailFactory® Device Control System (DCS) software components are responsible to manage, cache and forward the production data into our highly secure, reliable and available Cloud in Switzerland. There, the information gets extracted, transformed and loaded into the data warehouse. Afterwards the information is aggregated and stored in data cubes. The Business Intelligence application (dashboard) enables the end user to access and analyze the production data using a web browser. The analysis gives you detailed insight into which improvements are needed on the inserters or within your mail production process to increase the overall efficacy.

- We maintain and operate the Business Intelligence (incl. data warehouse) solution in a highly secure, reliable and available Cloud

- We maintain the IT infrastructure and manage the large amount of data

- State of the art web based graphical user interface for visualization and analysis

Your Benefits

- No in-house Business Intelligence specialists needed

- Reduced IT infrastructure costs

- Predictable costs due to rental model